B01D7K0090 ER308L – MIG Stainless Steel Welding Wire – 33 Lb x 0.035″

$98.00

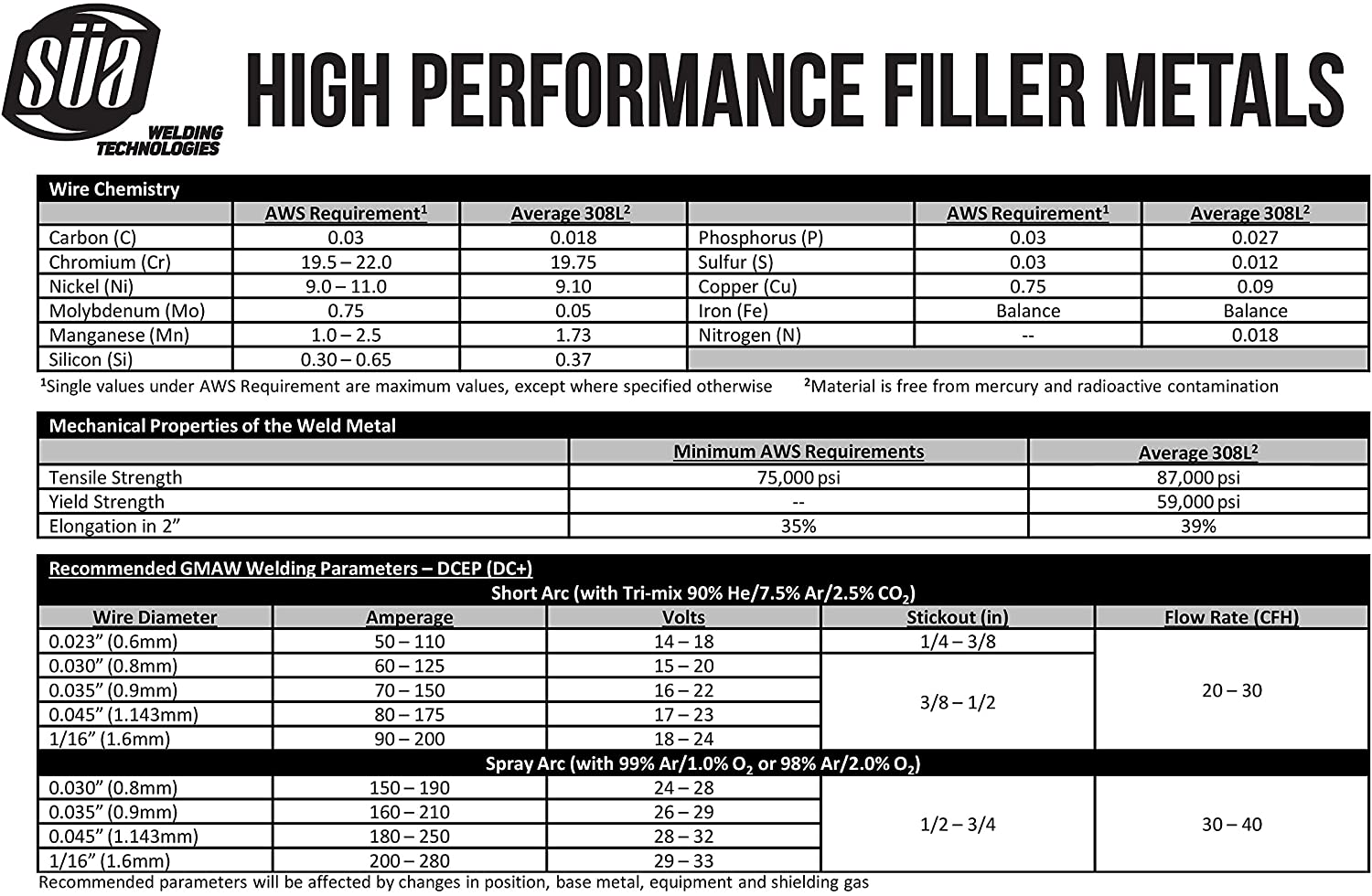

Size:0.035″ – (33 Lb)ER308L – Wire – MIG (GMAW) – Stainless Steel AWS A5.9 Welding Positions: All Introduction: The main component of 308L is ultra-low C-18Cr-8Ni, it is MIG wires that are widely used in welding austenitic stainless steel and it is all position welding. The weld-ability is good. Feeding wire smoothly will enable stable arc, excellent welding performance and spatter is very low. Ferrite in the deposited metal enables excellent corrosion-resistance and crack-resistance. Uses: It is widely used in petrochemical, pressure vessel, food processing machinery, medical equipment, chemical fertilizer equipment, textile machinery, nuclear reactor such as 022Cr19Ni10 (SUS 304L) and other materials of welding. Chemical Composition (%): Chemical Composition C Mn Si Cr Ni Requirement ?0.030 1.00~2.50 0.30~0.65 19.50~22.00 9.00~11.00 Typical test result 0.023 1.63 0.40 20.12 10.35 Chemical Composition Mo P S Cu Requirement ?0.75 ?0.030 ?0.030 ?0.75 Typical test result 0.37 0.37 0.37 0.37 Welding Parameters (DC+): Diameter (mm) F0.8 F1.0 F1.2 Welding Current (Amps) 70~150 100~200 140~220 Notes: 1. Shield gas: Must ensure not to operate with impurity shield Gas, Recommended Rate of mixed gas: Ar + 1-3% O2. 2. Operation flow rate of shield gas: 20-25L/min. 3. Electrode extension: 15-25mm 4. The welding should be operated in clean surface without rust, moist, oil contamination and dust. 5. To avoid bubbles protect from wind its speed reach 1.5 m/s. The above parameters are for reference purpose and depend on diverse factors. Run tests, evaluate and set your welding parameters before starting the welding job.

Make sure this fitsby entering your model number.

General purpose Stainless Steel MIG Wire for welding 19% chromium – 9% nickel austenitic stainless steels such as 304L, 308 L as well as stabilized grades 321 and 350

#1,477,604 in Automotive (See Top 100 in Automotive)#577 in Welding Wire

########

0

FALSE