B07VSFLNNY WF-007A Wire Feeder Coldfiller Wire Machine Digital Pulse TIG Welding Equipment for Automatic Argon Arc Welding Machine Plasma Brazing Welding

$348.00

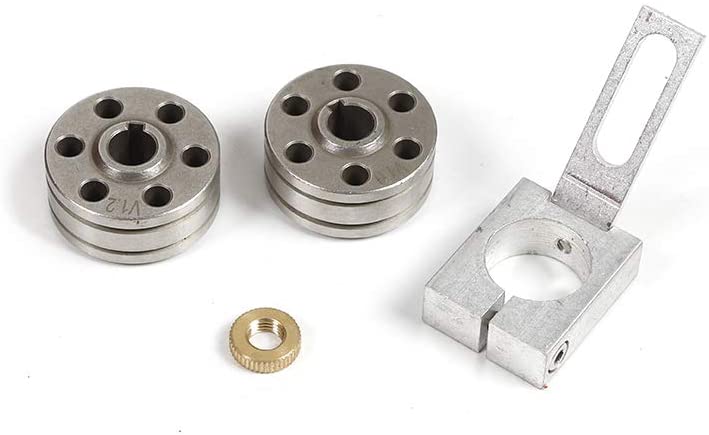

The main function characteristic: 1, automatic wire filling speed can be adjusted continuously; 2, drawing the wire back function; 3, delay the wire feeding function; 4, pulse feeding function; 5,continuous wire feeding function; 6, dual drive wheel feeding system, applicable to a variety of wire diameter of wire 7, applicable to all kinds of argon arc welding machine; 8, the standardization of products and components, according to the actualapplication of matching. 9, can be widely used in aluminum alloy, stainless steel, welding of low carbon steel and non-ferrous metal and many other materials; 10, argon arc welding, laser welding and other welding methods. 11, and can be applied to artificial, the welding process automation and robotplane. Technical Parameters: Voltage:AC110V 50hz/60hz The number of phases: phase HZ:50/60Hz Motor: DC permanent magnet Speed:1200rpm Wire table size:305mm Wire size:0.6mm,0.8mm,1.0mm,1.2mm,1.6mm,2.0mm Wire feed speed range:0-800 cm/min A pulsed wire feeding time: 0-10 Sec Pulse pause time: 0-10 Sec Time delay starting: 0-10 Sec Back to silking time: 0-10 Sec Power off time delay:0-5 Sec Step control:4 External input voltage:DC 0~10V Move the wire feeding speed:500 cm/min Move back to the spinning speed:100 cm/min High 420mm×wide 210 mm×length570 mm Weight:22 kgz Accuracy of speed:1%; Cold filler wire machine (argon arc welding wire feeding machine) Standard Parts List: 1,wire feeding machine*1 2, wire filling gun*1 3, wire feeding wheel * 1 4, wire feeding mouth /0.8/1.0/1.2/1.6 each 1

Make sure this fitsby entering your model number.

?Introduction?WF-007A Cold filler wire machine (argon arc welding wire feeding machine) is used for argon arc welding, laser welding, plasma welding, brazing welding process, withoutpreheating wire filling equipment for the molten pool.

29-Jul-19

0

FALSE